"If you’re sourcing custom glass cups, you need three things: durable products, reliable delivery, and a factory that understands retail standards. At Raylon Enterprise, we’ve delivered exactly that for over 20 years.

Since 2002, we’ve manufactured 11 million+ custom glasses for giants like Kmart, ASDA, TJ. We don’t just ‘make cups’ – we solve real problems: chipped edges, blurry prints, and missed deadlines that cost brands money and reputation.

This isn’t a sales pitch. It’s a practical guide sharing how a family-run factory in Guangdong became a trusted Custom Glass Cup Manufacturer for global retailers. Read on to learn what actually matters when producing drinkware that sells."

Why Experience Matters: 20 Years Solving Real Glass Manufacturing Problems

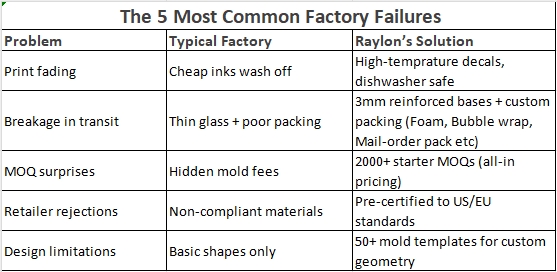

New factories learn through trial and error. At Raylon, our 20-year journey means we’ve already fixed the errors. Here’s what we prevent:

Proof in Partnerships

"After 3 failed suppliers, Raylon delivered 120,000 perfect promo beer mugs for our XXX launch. Their team even helped redesign handles to prevent stacking chips." — Sourcing Manager, Global Beverage Brand

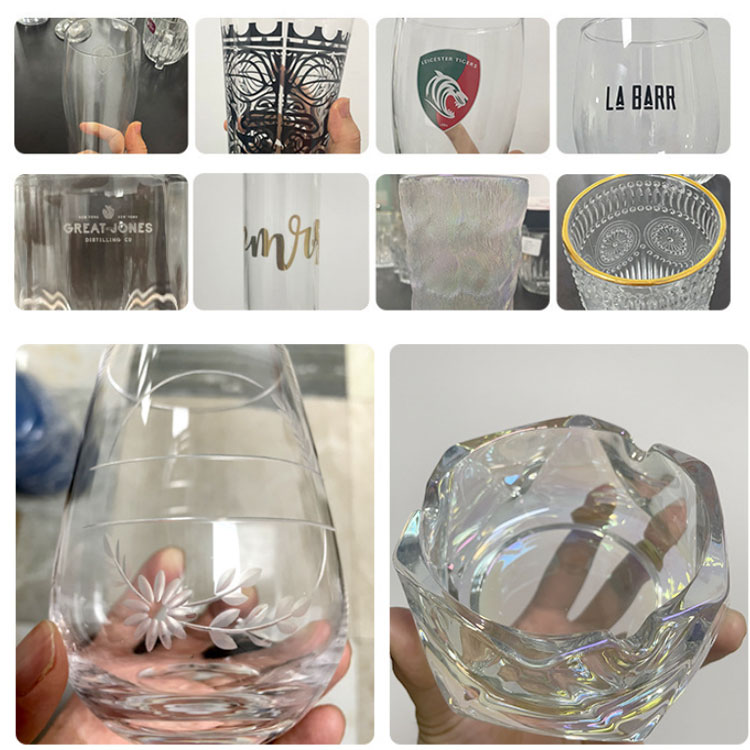

Inside Our Capabilities: More Than Just a Factory

We operate as your end-to-end drinkware partner with 3 specialized divisions:

Design & Engineering Team

30+ full-time designers creating 3D prototypes in <48 hours

Retail trend analysis: Track top-selling styles (e.g., 2024’s #1 seller: double-wall espresso cups)

Material library: 12+ glass types (including recycled options)

At Raylon Enterprise, every custom glass cup undergoes our engineered four-stage precision process. First, laser cutting guarantees ±0.05mm dimensional accuracy, eliminating sharp edges for safer handling. Next, decal designs vibrant, scratch-resistant artwork that survives hundreds of dishwasher cycles. Third, annealing ovens that optimize cooling curves, giving your glassware unmatched thermal shock resistance. Finally, our inspection system catches flaws invisible to the human eye. This isn’t just manufacturing; it’s 20 years of refining how quality drinkware should be made.

Your Product Roadmap: From Idea to Shelf

Phase 1: Design & Engineering (5-7 Days)

Free 3D rendering

Material selection guidance

Retail compliance checklist

Phase 2: Production (30-60 Days)

Real-time photo updates

Third-party lab testing available

Phase 3: Logistics (Flexible)

FOB/FCA/CIF/DAP/DDP options

Why Choose Raylon Enterprise?

✅ 20+ years expertise – 11 million glasses shipped

✅ All-in-one service – design, production, compliance, logistics

✅ Proven retail success – Costco, Tesco, AEON partnerships

✅ No surprises – All-inclusive pricing

✅ Eco-responsible – Certified sustainable manufacturing

Get Your Custom Glasses Right the First Time

Don’t risk your brand with inexperienced factories. Book a free consultation and receive:

1️⃣ 3D Design Mockup of your glassware

2️⃣ Lower MOQ (first order only)

3️⃣ Retail Compliance Checklist